Folders

Check out our impressive selection of innovative and high-performance folding solutions from respected brands such as Duplo and Multigraf. From straightforward, high-volume single fold applications to intricate cut, fold and perforate combinations we have something for you.

Booklet Making Solutions

Take your booklet-making capabilities to the next level. At Quadient Graphics, we are the proud supplier of a range of Duplo Bookletmaking systems to the Irish market. Capable of handling a variety of applications Duplo booklet makers provide the leading technology in the field...

Binders

From high volume to short runs, from fully automatic to semi automatic, and all binding types our Duplo solutions offer you the versatility flexibility and simplicity required in today's printing environment.

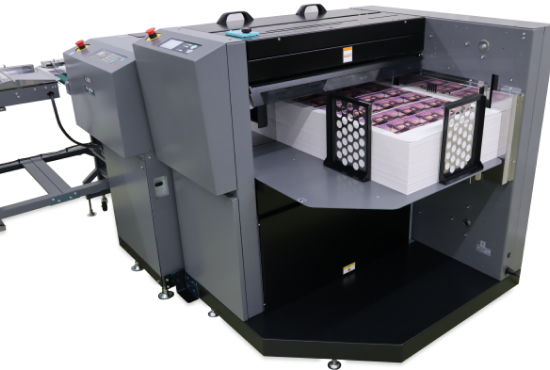

Collators

At Quadient Graphics Ireland, we are the proud supplier of a range of Duplo collating solutions. The Duplo range of collating machines allows your business to finish booklets and prints quickly and efficiently. Our collating solutions can be set up for any range of projects.

Creaser / Cutters

The Duplo range of creaser / cutters allow your business crease for digital colour print on a range of applications. With ease of use the Duplo range of creaser / cutters are innovative solutions for any digital print finishing.

Duplicators

Save a fortune on jobs. Duplicating systems offer the benchmark for productivity, economy & environmental sensitivity in high volume document duplication. With our range of duplicators you can copy a wide range of products such as cards, envelopes and photographs.

Guillotines

Quadient Graphics provide the highest standard, easy to use guillotines to the print & sign market. We offer a range of heavy-duty cutting solutions from leading brands such as Mohr & Ideal. With these top brands you can upgrade your cutting capabilities right away.

Laminators

A great print is nothing without the right finish. That is why laminating is such an important part of the print finishing process. Protect and preserve your high-quality prints with a state-of-the-art Komfi laminating solution from Quadient Graphics Ireland.Quadient Graphics provide the highest standard, easy to use guillotines to the print & sign market. We offer a range of heavy-duty cutting solutions from leading brands such as Mohr & Ideal. With these top brands you can upgrade your cutting capabilities right away.